SEMI S2/S8 Evaluation Quick Topics

Watch How We Perform Our SEMI S2/S8 Evaluations

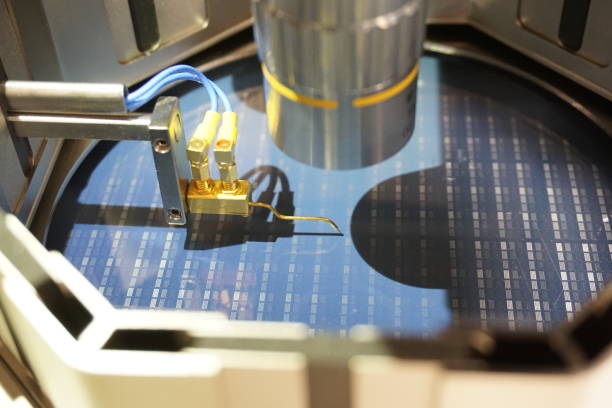

In this video, you will see a modified SEMI S2/S8 evaluation performed on custom equipment at an actual client’s facility in Fremont, California. The tests performed in this video are the actual tests used at every one of our clients locations and are the industry-standard for these types of machine functions and layouts.

What is a SEMI S2/S8 Evaluation?

A SEMI S2/S8 evaluation is a safety and ergonomics review of a semiconductor system.

The SEMI S2 Guidelines were created by the leaders of the SEMI industry to ensure every piece of equipment is compliant to regulatory requirements and is checked against a high standard of safety.

The topics range from fire protection, electrical hazard protection, mechanical hazard mitigation, chemical, radiation, noise and ergonomics hazards, ventilation requirements, emergency shutdown procedures, exhaust specifications, hazard warning alerts and labels, documentation requirements and more.

Why would you need a SEMI S2/S8 evaluation?

In the semiconductor industry, the SEMI S2 and S8 directives are relied upon as the gold standard for machine

evaluation and many buyers have even begun including them in their terms of contract.

Additionally, SEMI S2/S8 certification proves that your product fulfills the international standards for safety and

ergonomics, making international sales of semiconductor equipment an overall smoother process between buyers and

sellers.

A SEMI S2/S8 evaluation performed by LBIES provides the final report and technical file that is the key to end-user

acceptance of your equipment and can be considered as a form of buyers insurance in marketplace transactions.

What will and should be considered in a SEMI S2/S8 evaluation?

A typical SEMI S2/S8 evaluation is usually comprised of the following three standards:

- SEMI S2-0821 (Environmental, Health, and Safety Guideline for Semiconductor Manufacturing Equipment)

- SEMI S8-0218 (Safety Guideline for Ergonomics Engineering of Semiconductor Manufacturing Equipment)

- SEMI S10-0423E (Safety Guideline for Risk Assessment and Risk Evaluation Process)

This scope can vary, as some of our clients often opt for additional standards and sections due to specific insurance or facility requirements that their facilities or client’s facilities require for compliance.

Common SEMI S2 evaluation add-ons are SEMI S2 sections 21, 22, 23, for machines that deal with chemical and gas components.

The SEMI® Standards

For a list of all current and past SEMI standards please click here.

SEMI Standards and SEMI Sections

Things can get confusing when referencing SEMI Standards and SEMI Sections. For instance, performing a SEMI S10, if not properly described to an end user could mean two very different things: as a Standard you would be performing a SEMI S10 – Safety Guideline for Risk Assessment and Risk Evaluation Process evaluation, yet as a Section you would be performing a SEMI® S2 Evaluation Section 10 Hazard Alert Labels evaluation.

What is the difference? Well, a Section is derived from the SEMI S2 Standard and a Standard is its own stand-alone guideline alongside the SEMI S2 Standard itself.

Are you confused? We understand completely. To further illustrate this difference, all the current sections of the SEMI S2 Standard are listed below to demonstrate the depth of the SEMI S2 Standard:

The Sections of SEMI® S2

- SEMI® S2 Evaluation Section 9 Documents Provided to User

- SEMI® S2 Evaluation Section 10 Hazard Alert Labels

- SEMI® S2 Evaluation Section 11 Safety Interlock Systems

- SEMI® S2 Evaluation Section 12 Emergency Shutdown

- SEMI® S2 Evaluation Section 13 Electrical Design

- SEMI® S2 Evaluation Section 14 Fire Protection

- SEMI® S2 Evaluation Section 15 Process Liquid Heating Systems (SEMI® S3)

- SEMI® S2 Evaluation Section 16 Ergonomics and Human Factors

- SEMI® S2 Evaluation Section 17 Hazardous Energy Isolation

- SEMI® S2 Evaluation Section 18 Mechanical Design

- SEMI® S2 Evaluation Section 19 Seismic Protection

- SEMI® S2 Evaluation Section 20 Automated Material Handlers

- SEMI® S2 Evaluation Section 21 Environmental Considerations

- SEMI® S2 Evaluation Section 22 Exhaust Ventilation

- SEMI® S2 Evaluation Section 23 Chemicals

- SEMI® S2 Evaluation Section 24 Ionizing Radiation

- SEMI® S2 Evaluation Section 25 Non-Ionizing Radiation and Fields

- SEMI® S2 Evaluation Section 26 Lasers

- SEMI® S2 Evaluation Section 27 Sound Pressure Level

Take Heed: Semiconductor Equipment Resale Values Depend on Accurate SEMI S2 Reports

While many of these sections may not specifically apply to system(s) you may be designing or ordering for your specific manufacturing use cases (for example: if your system does not use lasers the Section 26 evaluation would not apply) it is important to be aware of this comprehensive list of S2 sections and if some of them do, in fact, apply to your system and you are choosing to skip them either willfully or out of error. This is because if the equipment gets resold to another company down the line, they may balk at some S2 sections not having been applied to the full SEMI S2 report and it could potentially block a sale or lower the resale value of the system itself on the open market.

SEMI S2/S8 addendum reports: when do they apply?

SEMI S2 addendum reports are a clear, simpler path forward over a full SEMI S2 report. These addendum reports are specifically drafted in situations where previously evaluated systems have received minimal revisions due to either parts scarcity, redesigns specified by the end user, name changes, or other functional adjustments, ex: adding a different type of sub-assembly like a chiller or heating element.

We covered this topic on SEMI S2 addendum reports and when they apply in our Ask Lewis Bass blog series back in September of 2021. The question from this blog post is copied verbatim from this blog post below along with our answer:

Hi Lewis Bass,

We’ve just finished building a semiconductor machine to the exact same specifications and with the exact same internal components as another machine that has already undergone testing and was found to be compliant to SEMI S2/S8 standards.

A new client of ours is requesting this new machine with a different name than the previous machine’s name.

Do I need to undergo an entirely new SEMI S2/S8 evaluation just because I’ve changed the name of the machine for one client?

Our Answer:

No, you do not need to undertake another series of SEMI S2/S8 evaluations of a machine with only a name change.

In situations like this, companies like Lewis Bass will provide your company with a SEMI S2/S8 Addendum Report.

An addendum report takes into account the original SEMI S2/S8 report for the previous machine in addition to the documentation, schematics, and BOM (bill of materials) for the newly built machine.

Once our engineering team is able to confirm that there has been no change to any design, combination of listed components, and machine layout and ergonomics, a simple SEMI S2/S8 Addendum Report is drafted explaining that the machine adheres to SEMI standards and that for all intents and purposes the machines are identical save for their names.

This SEMI S2/S8 Addendum Report is equivalent to having done a full SEMI S2/S8 evaluation of the identical machine with a different name and will pass muster as the machine changes hands down the line.

For situations where minimal changes have been made to the system:

SEMI S2 addendum reports performed on systems that have been previously evaluated for compliance to SEMI standards are evaluated against the changes in the BOM, schematics, and provided documentation for the modified system.

The resulting SEMI S2 addendum report provides the delta of the changes in the system which can then be outlined and noted in the addendum report along with supporting verbiage stating that the modifications are still within the acceptable ranges of conformity per each SEMI S2 section and standard it was evaluated against. A Lewis Bass engineer may also request additional supporting documentation for hardware-level modifications or additional sub-systems that were added to the new design to ensure these modifications and sub-systems are listed components and are safe to be included in the design.

As of July 31st 2024, Lewis Bass now offers SEMI S2 Addendum Reports as a service to our clients. If you would like a quote for this service, please click this link here to request a quote.

What is the process for performing a SEMI S2/S8?

As a general guideline, our engineer will perform the following tasks in coordination with your engineering team

below:

1) Review the machine’s manuals, BOM (Bill of Materials), and schematics.

2) Come to your facility and do a multi-day inspection.

3) Provide your team with a punchlist of items that failed.

4) Communicate back and forth with you to resolve all identified issues.

5) Start writing the report and putting together the Technical File.

6) Produce a draft report for your to review and make requests.

7) Provide the final report and technical file.

8) Provide a SEMI S2 certificate.

The SEMI Org: who they are and what they do

According to the SEMI website:

SEMI is a catalyst for connection, collaboration and innovation, helping the semiconductor industry to deploy lifechanging tech worldwide. SEMI Standards form the foundation for innovation in the microelectronics industry. The SEMI Standards process has been used to create more than 1,000 industry approved standards and guidelines, based on the work of more than 5,000 volunteers.

According to Wikipedia:

SEMI is an industry association comprising companies involved in the electronics design and manufacturing supply chain. They provide equipment, materials and services for the manufacture of semiconductors, photovoltaic panels, LED and flat panel displays, micro-electromechanical systems (MEMS), printed and flexible electronics, and related micro and nano-technologies.[1]

The SEMI Standards program was established in 1973 using proceeds from the west coast SEMICON show. Its first initiative, following meetings with silicon suppliers, was a successful effort to set common wafer diameters to be used in silicon manufacturing. This standardization helped the industry avoid a wafer shortage from 1973 to 1974, that had previously been anticipated. The standards would become internationally utilized over the years, through partnerships with the ASTM, the DIN, and other national standards organizations.[10] Before these standards, there were more than two thousand different specifications for silicon and by 1975 80% of all silicon wafers met with the SEMI standard.[11] It was first published annually as the Book of SEMI Standards.[12] With three new standards published annually in the mid-2000s, the book was eventually replaced with a CD-ROM,[13] and now standards are available online on an annual subscription basis.[14]

Today, more than 1,000 SEMI standards and safety guidelines are available to address all aspects of automated fabs. The standards are developed and maintained by over 5,000 volunteer experts representing more than 2,000 companies, working in 23 technical committees and 200 task forces.[15] High-profile standards include wafer dimensions and materials, factory efficiency and reliability, equipment interfaces, and environmental, health and safety standards.[15] In 2022, SEMI published first ever a pair of Cybersecurity Standards, to help protect against future cyberattacks on factory equipment. SEMI E187 – Specification for Cybersecurity of Fab Equipment, and SEMI E188 – Specification for Malware Free Equipment Integration. [16]

The four main equipment communication standards are the SECS-I (which stands for SEMI Equipment Communication Standards) established in 1978 that deals with communication protocol and physical definitions, the SECS-II established in 1982 that deals with message format, the GEM established in 1992 that refines the SECS-II, and the HSMS that supersedes SECS-I established in 1994.[17] The organization also provides safety and ergonomics guidelines, the first of which was the SEMI S2 developed in 1993, followed by the SEMI S8 in 1995.[18]

SEMI S2/S8 resources

Do you need a simple straight-to-the-point document covering SEMI S2 and the process involved? Download our SEMI S2 marketing cutsheet flyer here.

Is your system more complex than the sum of its electrical components? Are you using gas/chemicals/lasers in your system? Let this SEMI S2 scope questionnaire be your guide towards receiving an accurate quote from Lewis Bass. Download it here.

The above mockup is an example of what our SEMI S2 compliance Label looks like and what information is generally displayed on the label. Our labels in the field are made of durable metal material.