SEMI Compliance Addendum Reports: when are they needed?

Maintaining SEMI compliance is crucial for businesses in the semiconductor industry.

Instead of opting for a full SEMI S2 evaluation, SEMI compliance addendum reports offer a more efficient and straightforward alternative. These reports are especially useful when existing systems, previously evaluated, undergo minor changes. Such changes might include part replacements due to shortages, redesigns specified by end-users, name changes, or other functional adjustments.

For example, if a certified product requires a new sub-assembly like a chiller or heating element, an addendum report can suffice. This streamlined process ensures SEMI S2 compliance without requiring a full re-evaluation.

Cost Efficiency

Using an addendum report can significantly reduce costs, often by up to two-thirds compared to a full SEMI S2 evaluation. This makes it a cost-effective choice for companies aiming to maintain compliance without incurring the higher expenses of a full report.

Accelerated Market Access

Choosing a SEMI S2 addendum report also speeds up time to market, which is invaluable for manufacturers facing supply chain issues or customer-driven redesigns. These challenges often need quick resolution to meet shipment deadlines. Since the initial SEMI S2 evaluation would have already covered necessary measurements and documentation reviews, the addendum report allows for faster adjustments and compliance updates.

SEMI Compliance Addendum Reports Help Support Rapid Semiconductor Industry Expansion

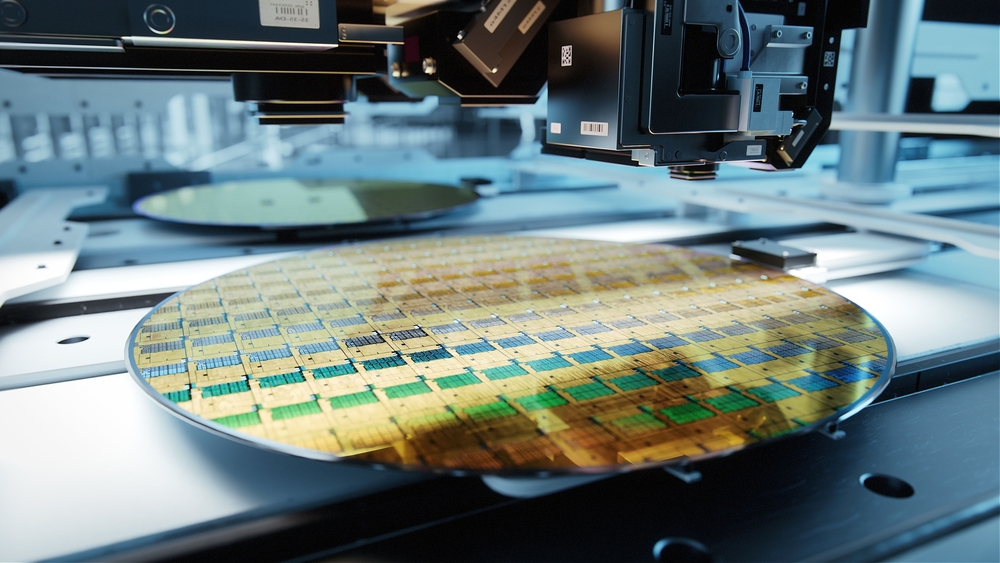

The semiconductor industry is growing rapidly, driven by increasing demand for advanced technologies in devices like smartphones and electric vehicles. As manufacturers strive to keep pace, maintaining compliance with SEMI standards becomes crucial. SEMI Compliance Addendum Reports provide a practical solution, particularly when minor adjustments are made to previously certified systems.

For instance, when a semiconductor manufacturing tool undergoes small modifications—such as component upgrades or new feature incorporation—an addendum report ensures continued SEMI compliance. This process saves time and resources while helping manufacturers quickly adapt to technological advancements, ensuring new products reach the market swiftly and meet high safety and quality standards.

What is the Process for Performing a SEMI Compliance Addendum Report?

To prepare for a SEMI compliance addendum report, our engineering team follows a detailed process with your company:

- Review the machine’s previous SEMI S2 report.

- Assess the changes in the machine’s composition, including BOM, schematics, and supporting documentation for changed or added components.

- Draft the addendum report for your review and feedback.

- Finalize the addendum report.

- Issue a new SEMI S2 certificate.

Addendum reports for systems previously evaluated for SEMI S2 compliance focus on the changes in the BOM, schematics, and provided documentation. The resulting report outlines these changes and provides supporting information, confirming that the modifications still fall within acceptable conformity ranges according to the relevant SEMI S2 guidelines.

Do you need a quote for a SEMI Compliance Report Addendum?

Do you have a need for any of our other services?

Lewis Bass can help your team identify the most common safety issues in your facility, along with providing immediate referrals to our trusted partners to address them on your behalf.

Not sure what service you need from us?

Take our service identifier quiz here.

Are you uncertain if your equipment is unlisted or not at your facility?

Lewis Bass has you covered here as well: download our unlisted equipment self-identification flyer here.

Do you have a need for an urgent machinery evaluation?

Please reach out to us using our contact form here or call/text us directly on our office line 408-942-8000. We are always available to help with rush jobs and permit-blocking safety situations at your facility.

Comments are closed.

One Reply to “SEMI Compliance Addendum Reports: when are they needed?”

[…] An addendum report can reduce costs by two-thirds for companies that should maintain compliance. For instance, if a certified product needs to be modified, the company can use an addendum report to avoid incurring the expense of a full report. […]