This Month in Electrical Safety: October 2025 Edition

As the leaves begin to turn and temperatures drop across much of the United States, October signals more than just the start of the fall maintenance season.

For many facilities, it is the ideal time to review electrical safety programs, conduct long-overdue preventive maintenance, and revisit the cornerstone of electrical hazard mitigation: the arc flash analysis.

Why October Is the Right Time for Arc Flash Review

Throughout the busy summer months, many industrial facilities focus heavily on meeting production schedules, expanding capacity, or integrating new systems. In that flurry of activity, essential safety documentation is often deferred or overlooked. October, by contrast, is the month when operations stabilize, allowing teams to step back and assess their electrical infrastructure in a more controlled and deliberate way.

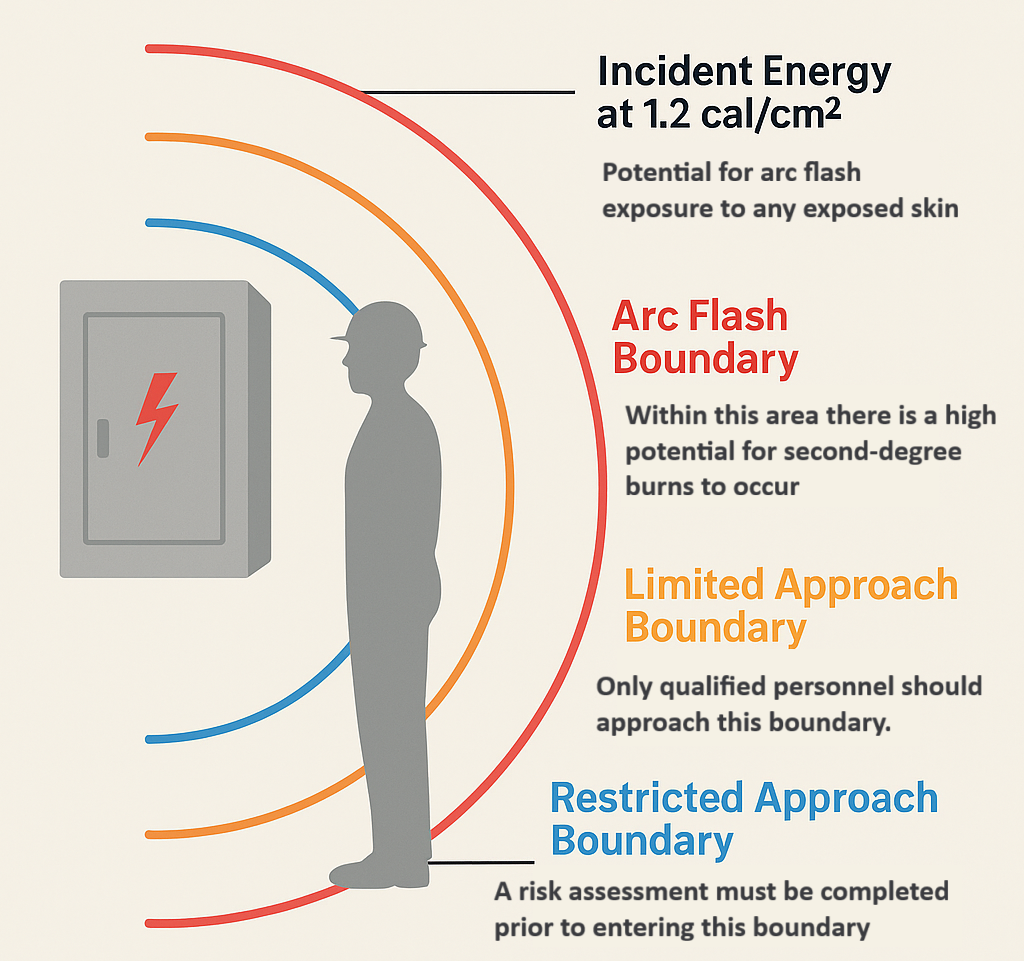

Performing an arc flash analysis during this period allows engineers and safety professionals to identify gaps in their existing labeling programs and to confirm that breaker settings, protective relays, and coordination schemes are still appropriate for current loading conditions. The National Fire Protection Association (NFPA 70E) and the Occupational Safety and Health Administration (OSHA 1910.333) both require that these studies be updated whenever there is a significant modification to the electrical distribution system. Yet many organizations still rely on studies that are five or even ten years old, long after equipment additions and transformer upgrades have altered system fault currents.

Common Findings from Field Evaluations in 2025

At Lewis Bass, our field evaluation engineers have observed a steady increase in outdated arc flash labels, missing personal protective equipment (PPE) boundary signage, and inconsistent single-line diagrams. These issues are not just clerical oversights; they represent real hazards for technicians and maintenance staff working on or near energized components.

We often encounter facilities where the coordination between upstream protective devices and local panel breakers has been compromised by incremental system changes. The result is a false sense of security: labels may indicate a lower incident energy than what would actually be experienced during a fault. A thorough arc flash analysis corrects these discrepancies by recalculating incident energy based on real-time system data and by verifying protective device clearing times under all credible fault conditions.

Another common finding involves facilities that have undergone energy-efficiency retrofits, such as variable frequency drive installations or capacitor bank adjustments. While these upgrades can reduce operational costs, they often alter fault current profiles and require re-evaluation to maintain compliance.

The U.S. Landscape: From Industrial Plants to Data Centers

Across the United States, demand for updated arc flash studies has been rising as more facilities modernize power distribution systems. Data centers, in particular, are under pressure to maintain uptime while adhering to strict safety protocols. These environments require a level of documentation precision that matches their technological complexity.

In manufacturing, the story is similar. Food processing plants, automotive assembly lines, and semiconductor fabrication facilities all face the same challenge: integrating new automation and control equipment without compromising worker safety. When an arc flash analysis is incorporated into a broader electrical safety management plan, it becomes not just a compliance exercise but a strategic tool that helps optimize operations and reduce downtime.

Global Momentum in Electrical Safety

Internationally, awareness around electrical hazards continues to expand. Canada’s CSA Z462 standard and the European IEC 61482 series both mirror the intent of NFPA 70E by emphasizing proper documentation, risk assessment, and worker training. Multinational corporations with sites in multiple jurisdictions are beginning to harmonize their internal safety programs so that one study framework can satisfy multiple regional requirements.

Lewis Bass has recently assisted clients with global operations in developing standardized arc flash analysis templates that account for both U.S. and international testing criteria. This approach simplifies auditing, improves training consistency, and ensures every facility is held to the same rigorous standard of safety.

This Concludes Another Month in Electrical Safety.

No matter the size or location of your operation, an updated arc flash analysis remains one of the most effective and affordable safety investments available. It provides a clear, data-driven picture of electrical hazards, allowing management to assign accurate PPE levels, plan safe work procedures, and minimize unplanned downtime.

If your study is more than five years old, or if your facility has undergone any electrical upgrades, contact us for a free quote. Our team can perform comprehensive short-circuit, coordination, and arc flash assessments while verifying the integrity of your labeling and documentation.

Electrical safety is not a once-and-done effort. It is a living system that evolves with your equipment and workforce. Make this October the month you bring your facility back into full compliance and give your team the confidence to work safely around energized systems.

Stay vigilant, stay compliant, and join us again next month for the November edition of This Month in Electrical Safety.