SEMI’s F47 Voltage Sag Immunity Standard History From 1996-2006

SEMI F47 testing got its start with the demanding needs of the semiconductor industry

What we now know as SEMI F47-0706 testing began as a series of research experiments conducted by The Electric Power Research Institute (EPRI) in the late 1990s under Section 24: Power Quality in the Semiconductor Industry.

Industry participants and contributors to this study included just under thirty fortune 500 companies including AMD, Applied Materials, IBM, Motorola, and many more well known industry stalwarts.

Why should semiconductor companies care about F47 testing?

AC operated electronic equipment are vulnerable to momentary losses of AC voltage, which are known as voltage sags. Voltage sags are commonly caused by lightning, accidental short circuit, loose connection, starting of large motors (or air-conditioners) or abnormal use of the AC mains. In sensitive and critical applications, such as semiconductor material processing and medical operation, voltage sags may result in serious problems.*

* source: https://ieeexplore.ieee.org/document/5157842

From EPRI’s Section 24 in 1996 to today’s SEMI F47-0706, the current standard in force since 2006, what exactly has changed with regards to testing semiconductor equipment for voltage sag immunity in the ten years between?

F47 Testing Started with EPRI’s Section 24

There were some key objective and outcomes from the Section 24 study that helped catalyze the semiconductor industry toward a common goal: a testable standard for voltage sag.

These objective and outcomes were:

- Identifying the most critical processes and most vulnerable devices in the semiconductor-fabrication process along with the power requirements for these processes and devices, combining user experience and laboratory testing as needed.

- Developing appropriate system compatibility criteria and test protocols (considering IEC, IEEE, SEMI, and other related standards) that could establish baseline performance criteria for semiconductor-fabrication tools.

- To make recommendations for improving the immunity of tools, applying power conditioning, and mitigating power quality problems in semiconductor-fabrication processes.

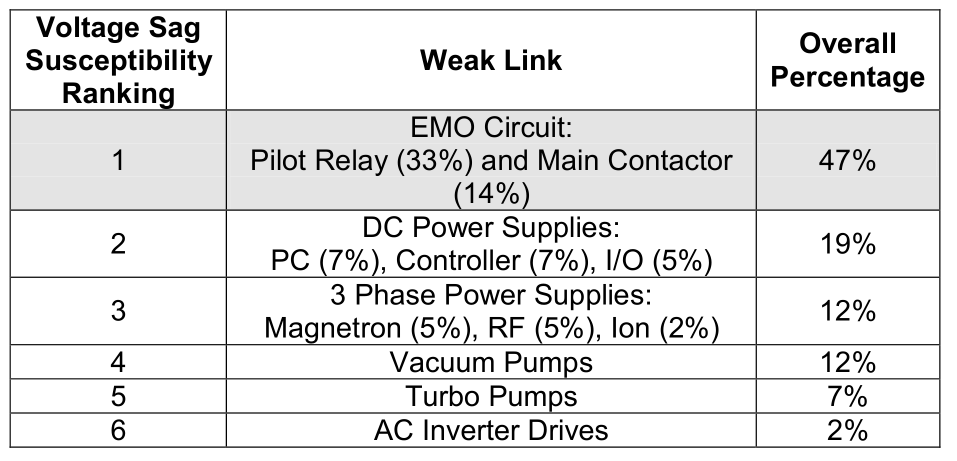

Section 24 also helped identify the most common reasons for tool susceptibility to voltage sag.

Here are the the most common reasons by overall percentage below:

The First SEMI F47-0200 Standard was Released in 2000

The original SEMI F47-0200 (voltage sag immunity) was found to be highly successful in reducing service costs and increasing tool reliability and uptime.

For semiconductor equipment to be considered compliant to this standard, equipment had to have the specified immunity characteristics against voltage sags without the use of batteries.

SEMI F47-0200’s intent was to lead to improved selection criteria for sub-components and improvements in equipment systems design.

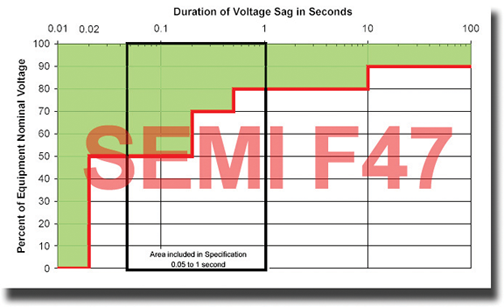

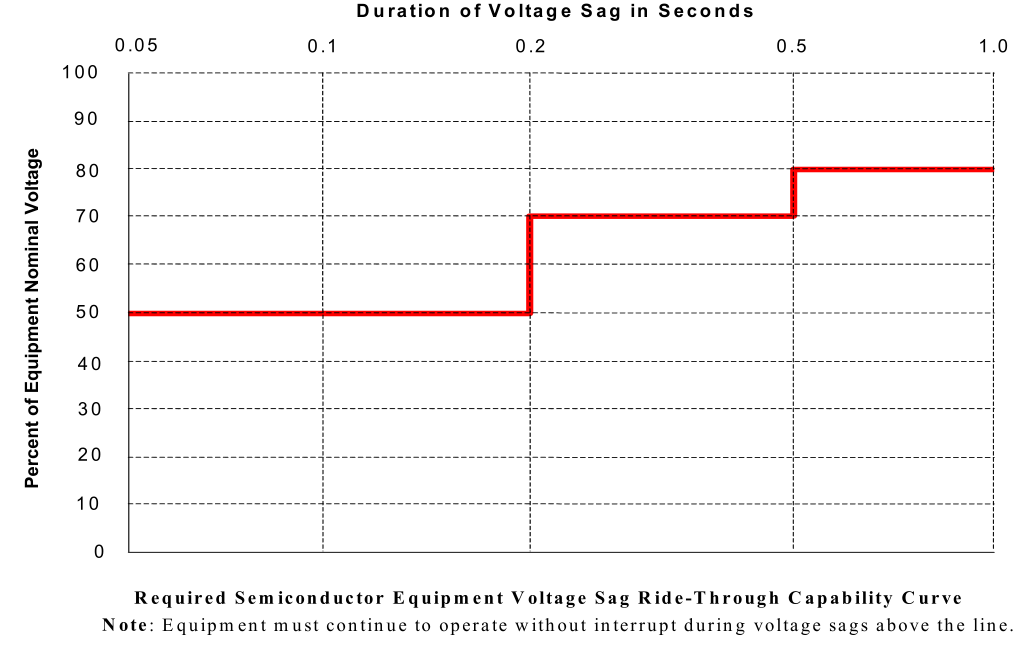

The original SEMI F47-0200 voltage requirements are indicated on the graph below:

The Second SEMI F47-0706 Standard was Released in 2006

Since 2000, Semiconductor Manufacturers, Tool Suppliers and Compliance Testing Companies had amassed a significant technical and practical knowledge base related to testing under the older SEMI F47-0200 standard.

The findings from testing performed to the old F47 standard were readily applicable to, and necessary for streamlining the testing process in, the next refresh cycle in 2006.

So, what exactly changed for F47 testing between 2000 and 2006?*

- Removal of the 50ms, 50% Vnom Test Point.

- Referencing of test durations are now presented only in cycles – with specific values for 50 and 60 Hz.

- Equipment must now pass at the test point levels rather than “above the defined line”.

- Compliance with the new SEMI F47-0706 is defined by passing three test points rather than compliance to a “Curve” as defined in SEMI F47-0200.

- Test vectors are defined as the original SEMI F47-0200 left this information implied.

- Single-Phase test vectors are the same.

- Three methods of allowable phase-to-phase test vectors are allowed.

- Pass/Fail criteria is broken out now for tooling equipment and subsystems

- Tools still use interrupt criteria.

- Subsystems now have three classes of response(s).

- Specific requirements of certification documents are defined.

- A Significant related information section aids the reader in a more in-depth understanding of intent.

- Addition of a section addressing how to use the specification for procurement of tools, subsystems and components that are compliant to SEMI F47-0706.

- Standard specifically states that three-phase sags are not required.

*Source: Overview of SEMI F47-0706 as presented by Chuck Thomas of EPRI at SEMICON Japan 2006

Will there be a successor to F47-0706 anytime soon?

The updated F47-0706 standard has proven itself robust and comprehensive enough for the vagaries and complexities associated with the changing semiconductor industry’s needs.

SEMI F47-0706 was last reviewed for potential changes in late 2011 as all SEMI standards are up for review in 5 year cycles. The result was re-approval of the same SEMI F47 standard as described below in this snippet from an official SEMI press release:

To ensure standards that are up-to-date, SEMI Regulations require that all current standards are reviewed every five years. Last published in 2006, SEMI F47 was maintained by The North America Facilities Committee. Alex McEachern (Power Standards Lab) formed the F47 Review Task Force to conduct the review process in October 2011.

F47 was circulated among tool vendors, end users, testing labs, and associated parties, and based on their input, it was determined that no technical change was needed. The standard was issued as a re-approval ballot to the global Facilities Committee in April 2012, and no reject votes were received. The ballot passed technical committee review, and is now published as SEMI F47-0706 (Reapproved 0812) – Specification for Semiconductor Processing Equipment Voltage Sag Immunity.

SEMI F47-0706 has not been re-evaluated for changes since 2012 and remains in force in the semiconductor industry as the recommended testing standard as of the time of this blog post’s publish date.

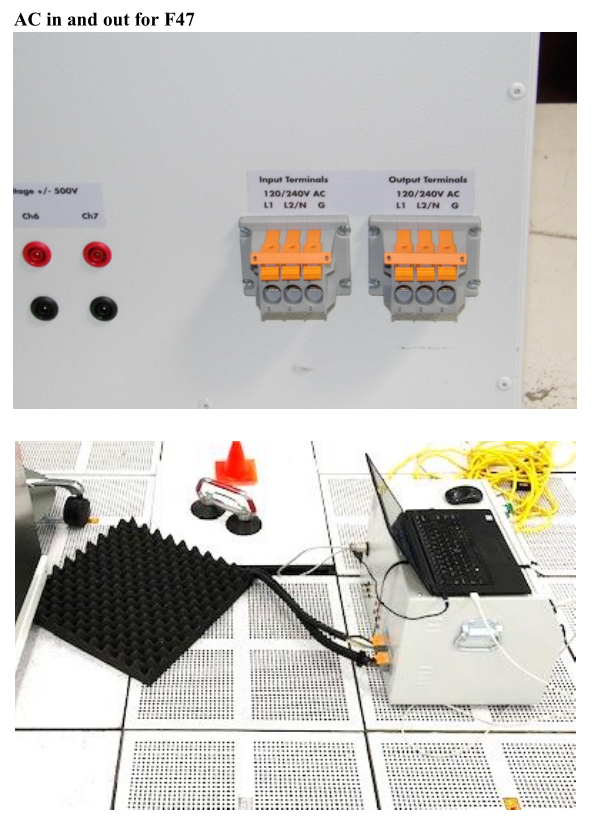

Are you looking for F47 testing services?

Reach out to Lewis Bass with details on the semiconductor equipment you’ll be needing the test performed on. We’ll be most interested in the machine’s operating manual and associated documentation on its operation and installation location in your facility.

Our trusted industry partner, Atlas Compliance, offers F47 testing services through us as part of our SEMI S2/S8 evaluations we perform for your clients.