The Benefits of Field Labeling Unlisted Equipment (and What Happens if You Don’t!)

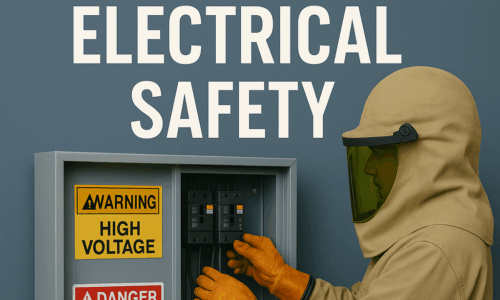

If you’ve ever been involved in a commercial or industrial project that required electrical equipment, you’ve probably come across the term “field labeling.”

Now, if that phrase didn’t immediately raise a flag in your mind, don’t worry—you’re not alone. Field labeling isn’t exactly the most glamorous part of the job, but it’s a critical one, especially when dealing with unlisted equipment. Whether you’re an electrician, a contractor, or a project manager, understanding the importance of field labeling can save you from headaches, delays, and possibly even some legal troubles. Let’s break it down.

First Off, What is Field Labeling?

In the electrical world, not all equipment comes off the shelf with a nice QPS (QPS Laboratories) or ETL (Intertek) mark that says it’s safe and up to code. Sometimes, equipment is custom-built, refurbished, or modified in ways that make it impossible for manufacturers to give it that safety mark beforehand. That’s where field labeling comes in.

Field labeling is essentially a safety inspection and certification process conducted on-site, usually by a Nationally Recognized Testing Laboratory (NRTL) like QPS or ETL. An inspector comes out, evaluates the equipment, checks for compliance with relevant safety standards (like the National Electrical Code, or NEC), and—if everything checks out—slaps a label on it that says, “Yes, this equipment is safe to use.”

The Benefits of Field Labeling Unlisted Equipment

So, why bother with field labeling? Can’t you just skip it if everything looks fine? Not exactly. Here’s why field labeling unlisted equipment is a good idea:

1. Safety First (Always)

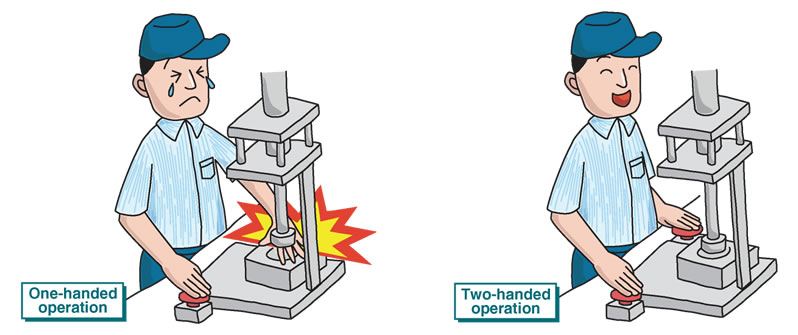

Electrical systems can be unpredictable. Just because a piece of equipment works doesn’t mean it’s safe. Field labeling ensures that unlisted or custom equipment meets the same safety standards as listed equipment. This means it’s been evaluated for proper grounding, wiring, and other safety features that protect against fires, electric shocks, and other potential hazards.

Imagine installing a custom-built machine that later sparks a fire because it wasn’t properly inspected. That’s a disaster waiting to happen, and no one wants to be responsible for that.

2. Code Compliance

The NEC requires that all electrical equipment be listed and labeled. If you’re using unlisted equipment, field labeling ensures that you’re in compliance with these regulations. Most jurisdictions won’t give you the green light for final inspections or approvals without it. So, unless you want your project stalled or hit with a violation, field labeling is your best bet.

3. Smooth Inspections

Ever had an inspector walk in and immediately point out a piece of equipment that’s missing a label? That’s the kind of situation that causes delays. Having unlisted equipment field labeled before the inspector shows up ensures that your inspection process goes a lot smoother. It’s one less thing to worry about when trying to get your project across the finish line.

4. Liability Protection

Skipping field labeling could open you up to serious liability issues. If an unlisted piece of equipment malfunctions and causes injury or property damage, guess who’s potentially on the hook? The installer, the contractor, maybe even the owner. By ensuring equipment is field labeled, you’re protecting yourself and your company from being held liable for any mishaps down the line.

The Downsides of Skipping Field Labeling

Now, what happens if you decide to skip field labeling unlisted equipment? Well, here are some of the potential downsides:

1. Project Delays

You can’t get around it—most inspectors won’t pass an unlisted piece of equipment that hasn’t been field labeled. This means you could be facing significant delays if you try to cut corners. Even worse, you may need to remove and replace the equipment entirely, which can be a costly and time-consuming process.

2. Legal and Regulatory Risks

Ignoring field labeling requirements could get you in trouble with local authorities or even OSHA. Failure to comply with NEC regulations can lead to fines, penalties, and potentially, a shutdown of your project. Plus, if there’s an accident, you could be looking at lawsuits or legal action from injured parties.

3. Increased Insurance Costs (or Denials)

Insurance companies like to see that you’ve taken all necessary precautions to ensure safety. Skipping field labeling could raise red flags with your insurer. In the worst-case scenario, they might deny coverage in the event of an incident involving unlisted equipment. That’s not a risk worth taking, especially when a field label can prevent it.

4. Damage to Your Reputation

If you’re a contractor or installer, your reputation is everything. Failing to properly field label unlisted equipment can damage your credibility and reliability. No one wants to be known as the company that cuts corners on safety and compliance. It’s a fast track to losing clients and future business.

Conclusion: Field Labeling is Non-Negotiable

At the end of the day, field labeling unlisted equipment is more than just a box to check off—it’s about ensuring safety, compliance, and peace of mind. While it might seem like an extra step, the benefits far outweigh the downsides. Whether it’s protecting your team, avoiding project delays, or staying out of legal hot water, field labeling is a smart move for any project involving unlisted electrical equipment.

So, next time you’re faced with unlisted equipment, don’t skip the field labeling process. It’s not just a requirement—it’s an investment in safety and success.

What did you learn in this week’s blog? Find out!

#1. Is field labeling necessary for unlisted or custom-built electrical equipment to ensure it meets safety standards?

#2. Can skipping the field labeling process for unlisted equipment lead to project delays and failed inspections?

#3. Does field labeling protect against liability issues in the event of an equipment malfunction?

#4. s field labeling optional according to the National Electrical Code (NEC) for unlisted electrical equipment?

Do you have a need for our services?

Lewis Bass can help your team identify the most common safety issues in your facility, along with providing immediate referrals to our trusted partners to address them on your behalf.

Not sure what service you need from us?

Take our service identifier quiz here.

Are you uncertain if your equipment is unlisted or not at your facility?

Lewis Bass has you covered here as well: download our unlisted equipment self-identification flyer here.

Do you have a need for an urgent machinery evaluation?

Please reach out to us using our contact form here or call/text us directly on our office line 408-942-8000. We are always available to help with rush jobs and permit-blocking safety situations at your facility.