What is EMC testing?

If you’ve ever asked yourself, “What is EMC testing?” you’re already stepping into a crucial part of product compliance for Europe (CE) and the UK (UKCA).

EMC testing ensures that your product can coexist with other electrical devices without causing or experiencing electromagnetic interference (EMI). Without passing these tests, your product may not meet regulatory requirements, preventing you from selling it in Europe or the UK. This blog will help you to understand why this is an essential step in product certification and how its role in CE and UKCA testing is necessary.

How EMC Plays a Part in CE and UKCA Mark Testing

Electromagnetic compatibility testing (EMC) plays a key role in achieving CE marking in Europe and UKCA marking in the UK. Both marks signify that a product meets the safety, health, and environmental standards set for those regions. Specifically, the EMC directive ensures that products neither emit electromagnetic disturbances nor are disrupted by them. This guarantees functionality in real-world conditions.

To obtain CE or UKCA marking, products undergo several tests to confirm they won’t interfere with other equipment or fail when exposed to interference themselves. EMC testing is vital for both regulatory compliance and providing a better user experience in interconnected environments like homes and industrial spaces. Simply put, you can’t obtain CE or UKCA certification without passing this step, which underlines its importance for products entering the European or UK markets.

The History of EMC Testing

Understanding EMC testing requires a quick look at its origins, long before it became a formal requirement in EU and UK product standards. EMC testing began to develop in the mid-20th century when the rise of electrical devices in homes, factories, and offices caused interference between systems, leading to malfunctions. Governments and industries recognized the need for standardized regulations to control electromagnetic interference.

In Europe, this led to the introduction of the EMC Directive in 1989. This directive laid the foundation for today’s CE marking EMC testing requirements. Over time, standards evolved to address new technologies and electromagnetic challenges. After Brexit, the UK developed its own UKCA system, which closely mirrors CE requirements, particularly the focus on EMC testing.

What Tests Does EMC Encompass and How is the Testing Performed?

EMC testing isn’t a single test but a series of evaluations designed to assess a product’s ability to operate in its intended environment without causing or being affected by electromagnetic interference.

Typically, it includes two types of tests:

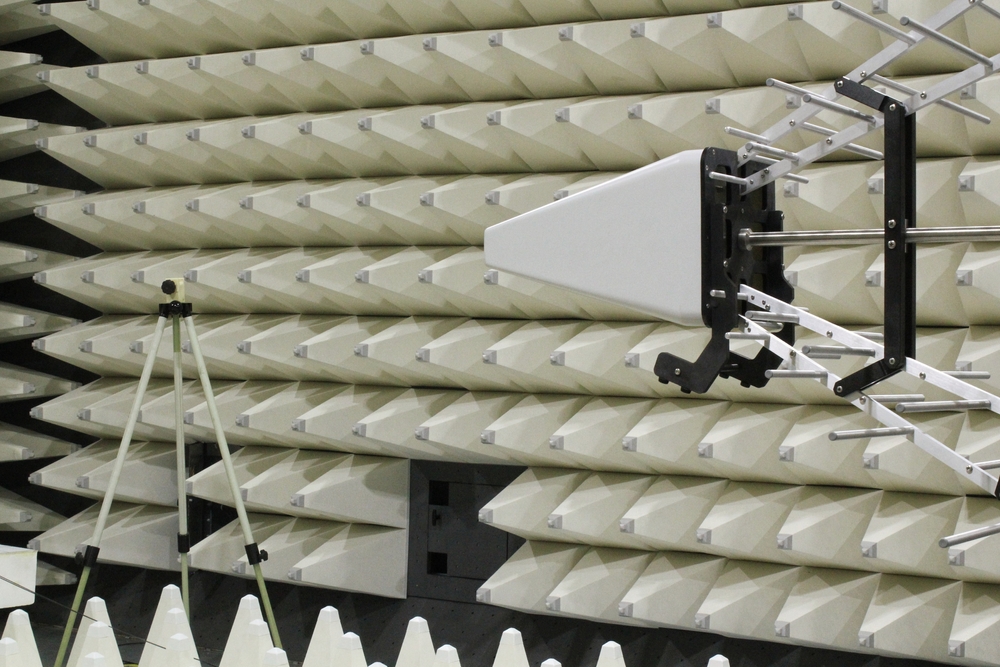

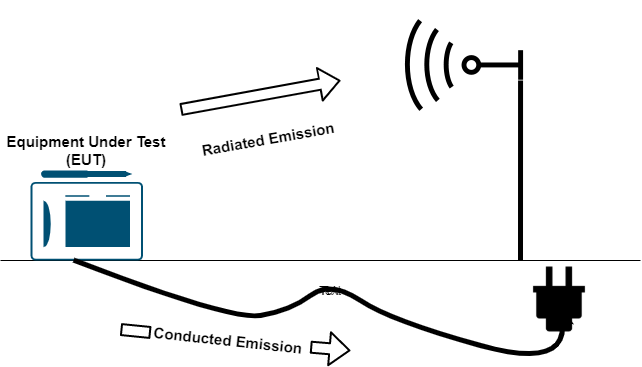

Emission Testing: This test checks whether the device emits electromagnetic interference that could disrupt other equipment. The test measures disturbances across various frequency bands and ensures emissions stay within acceptable limits.

* Image source: https://www.analogictips.com/what-are-some-common-emi-emc-tests-faq/

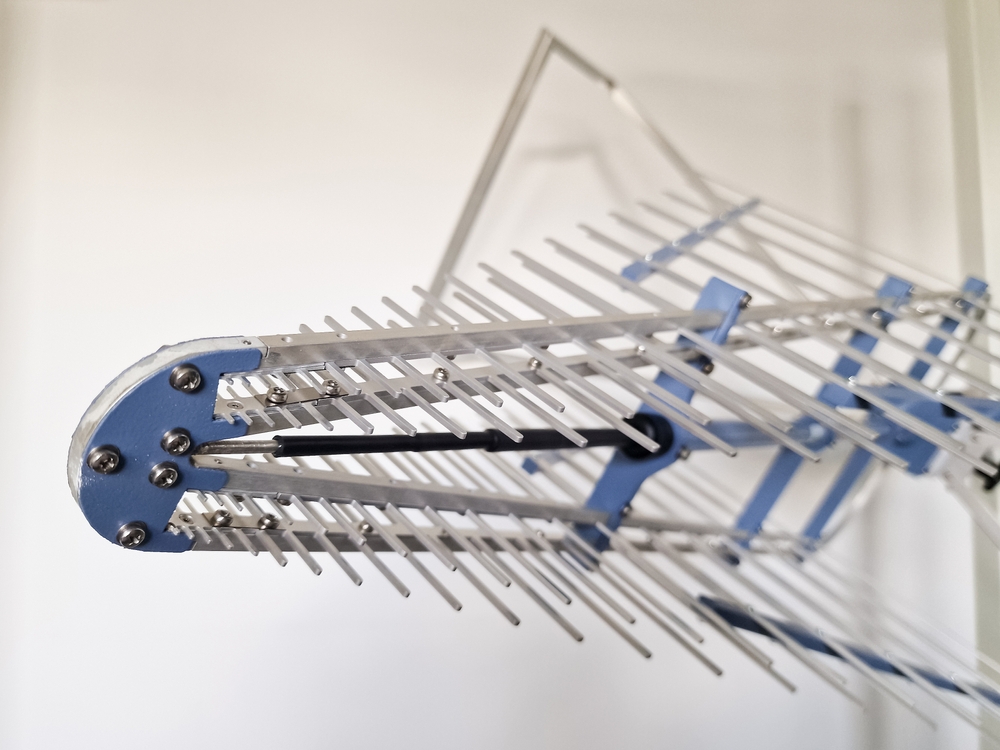

Immunity Testing: The counterpart to emission testing, immunity testing evaluates the device’s ability to resist external interference, like radio frequencies or nearby electrical equipment. The product must remain functional even in noisy environments.

* Image source: https://emcfastpass.com/emc-testing-beginners-guide/emc-immunity-testing/

These tests are typically conducted in specialized labs, often using anechoic chambers that isolate external radio frequencies. By replicating real-world conditions, these tests ensure that your product will perform reliably once it’s in use.

Common EMC Testing Failures and Potential Resolutions

Now that we have a better understanding of what EMC testing consists of, it’s important to also recognize that passing these tests isn’t always easy. EMC testing is complex, and even well-designed products can fail. Common reasons for failure include:

- Poor PCB Layout: Poorly designed circuit boards may cause unintentional emissions or fail to resist external interference.

- Inadequate Shielding: Electrical components need proper shielding to prevent emissions from leaking out or external EMI from entering.

- Inconsistent Grounding: Grounding problems often cause excessive conducted emissions, leading to test failures.

Fortunately, most EMC failures can be resolved through design modifications. Improving shielding, rerouting PCB traces, or enhancing grounding design are effective solutions. Sometimes, integrating filtering components like ferrite beads or capacitors can help suppress EMI.

Partnering with an experienced EMC testing lab is essential for quickly identifying and solving these issues. With the right guidance and adjustments, even tough EMC problems can be corrected, allowing your product to achieve full compliance for the EU or UKCA markets.

Do you have a need for EMC testing services?

Whether you are seeking EU compliance via CE Marking your product or UKCA Marking for the ability to sell your product in the UK, Lewis Bass can help assist with your project’s need for EMC testing services.

Please reach out to us using our contact form here or call/text us directly on our office line 408-942-8000 to get started with your request.