When to consider adding seismic anchoring to your equipment

If this blog’s featured image got your attention…

Then you are now probably keenly aware of one potential result from not using seismic anchoring in your facility. Seismic anchorage can be seen in many forms in facilities and can even apply to equipment installed on moveable caster systems as we saw in a recent Ask Lewis Bass blog post on this topic.

When should you consider and/or be required to use seismic bracing?

The first “when” is the most obvious one: if your facility is located in a seismically active location you should definitely consider seismic bracing for any sensitive equipment or machines that may pose tipping hazards or loss of both tangible and intangible company assets (data centers and server racks are a common concern).

The second “when” is also a requirement in US states like California. The American Society of Civil Engineers (ASCE) drafted seismic bracing requirements that concern machinery or equipment that meets the following two conditions:

Section 13.1.4 item 6c: Any component weighing more than 400 pounds.

Section 13.1.4 item 6c: Any component where its center of gravity is more than 4 feet above the floor.

There are exceptions to seismic anchoring

In the ASCE 7-10 Chapter 13 Seismic Design Requirements for Nonstructural Components Section 13.1.4 “EXEMPTIONS” a whole list of exemptions is provided for equipment that is suspended, single hangar conduit, or equipment/component related. You can find these exact exemptions in the presentation drafted by BICSI here.

California-Specific Exemptions

Per the 2013 California Building Code, Section 105.2, item 13; “Non-fixed and movable fixtures, cases, racks, counters and partitions not over 5 feet 9 inches (1753 mm) in height” are NOT required to be braced or anchored.*

*Source: https://medium.com/@goSkwerl/what-is-the-height-requirement-that-triggers-seismic-bracing-of-mobile-laboratory-equipment-in-ca-26cc4063fba3

What types of seismic anchorage can be deployed?

Seismic anchoring of equipment and machines can vary greatly by the type of facility (Industrial, biotech, clean rooms, etc) in which they are installed.

Floor Anchoring

For heavy machinery/equipment with a high center of gravity at least 4 feet above the floor (and specially when the legal limit of 400 lbs has been reached) you are looking at seismic anchorage that will be directly attaching it to the floor.

This can be done in a variety of ways, one of which involves braces drilled directly into the machine/equipment and then bolted to the floor. In special cases where the machine/equipment is of a delicate nature or holes cannot be drilled into it, special braces can be installed that hold the machine/equipment in place that are only bolted to the floor.

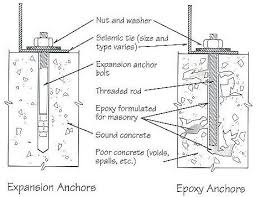

The following pictures demonstrate these two types of floor installation and the floor bolting requirements to meet the seismic anchoring codes.

The first picture on the left demonstrates anchorage with bracing only being drilled/mounted into the floor, the second image demonstrates the techniques that can be used to mount both types of the plates to the floor, and the final image on the right show seismic bracing that is drilled into the machine and into the floor.

Wall Anchoring

This type of seismic anchoring is most commonly used for very tall racks, shelving, and machinery that are positioned against a wall. Equipment/machines can be bolted to the wall in similar fashions as with floor anchorage, depending on the layout/functionality of the machine or equipment being anchored. In the below pictures a refrigerator and a chemical cabinet are bolted directly to the wall while the shelf on the right is simply braced with the bolts only being present in the wall itself.

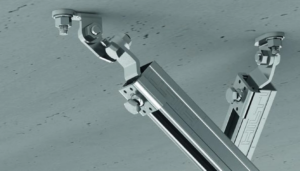

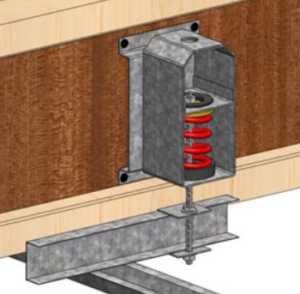

Ceiling Anchoring

Ducting, wiring, and tubing are commonly anchored to ceilings in accordance with seismic anchoring code, but what about machines and equipment?

In certain cases it makes more sense to seismically anchor machines and equipment to the ceiling due to either the close proximity of other machine/equipment or certain instabilities or insufficient floor materials that don’t allow for the solid, code-abiding floor anchorage to be deployed effectively.

The below three pictures show different styles of seismic anchoring from the ceiling and one application where a machine is fully elevated off the ground for seismic safety.

How are seismic anchors manufactured and installed?

The process of deploying seismic anchorage is always performed in the following steps:

- Securing a permit from your city for work start.

- Moving and installing your equipment and machinery to their final resting places in your facility.

- Measurements are taken of the equipment or machinery’s clearance to the ground below.

- Fabrication of the anchor plates.

- Installation of the anchor plates and inspection by the city and a special inspector for code compliance.

Do you have a need for seismic anchoring services?

Lewis Bass can help your team identify and seismically anchor machinery and equipment in your facility through referrals to our trusted partners.

Please reach out to us using our contact form here or call/text us directly at our office line 408-942-8000. We are always available to help with rush jobs and permit-blocking safety situations at your facility.