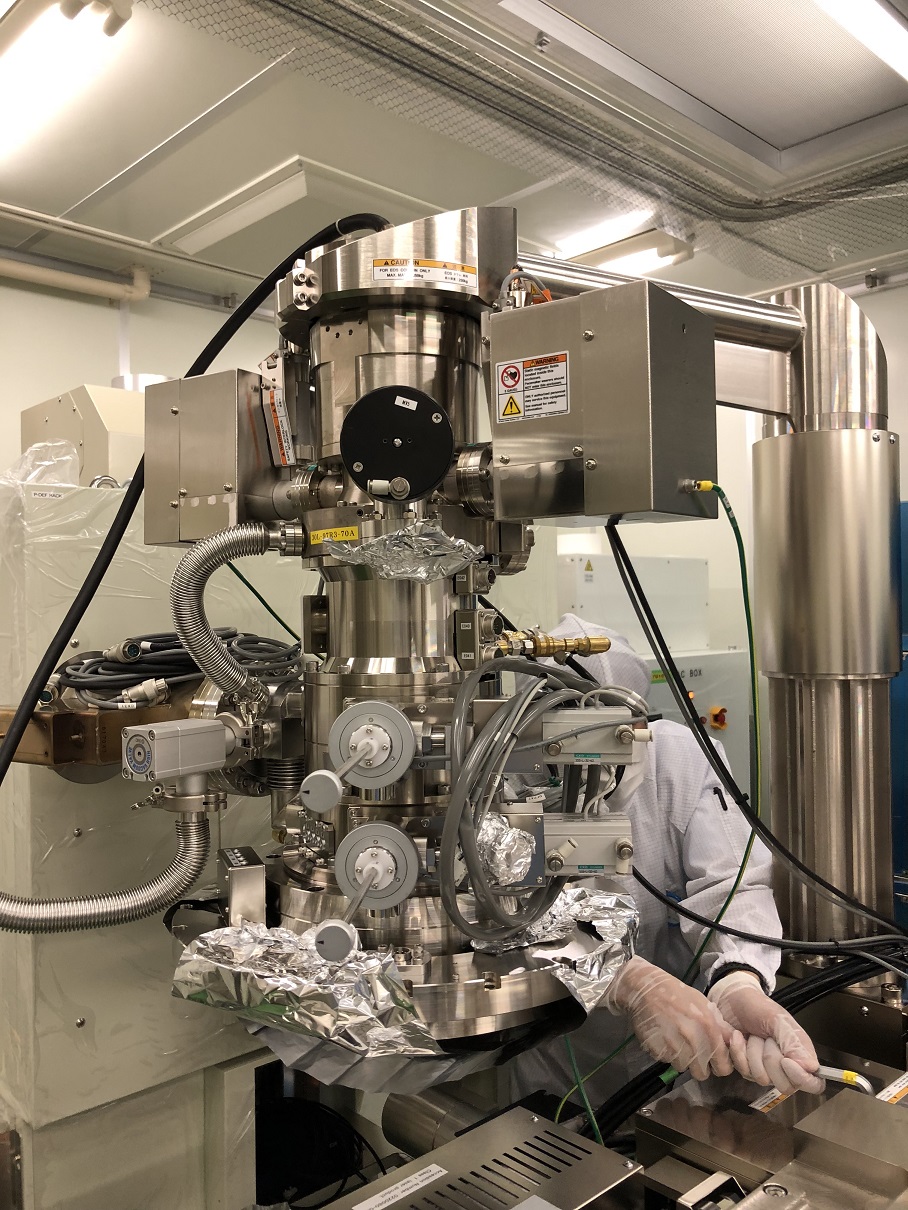

LBIES’s SEMI S2/S8 Evaluations Ensure Operational Safety and Serve as a New Buyer’s Safeguard

What Are The SEMI S2/S8 Guidelines And What Do They Evaluate?

SEMI S2/S8 Guidelines were created by the leaders of the SEMI industry to ensure every piece of equipment is compliant to regulatory requirements and is checked against a high standard of safety.

The SEMI standards encompass topics ranging from fire protection, electrical hazard protection, mechanical hazard mitigation, chemical, radiation, noise and ergonomics hazards, ventilation requirements, emergency shutdown procedures, exhaust specifications, hazard warning alerts and labels, documentation requirements, voltage-sag through F47 testing, and more.

Lewis Bass, the founder of our company, was instrumental in helping draft the SEMI S2 standards, drawing heavily from material he premiered in his comprehensive book on product safety liability. We are proud to continue offering SEMI S2/S8 evaluations with the same rigorous set of standards Lew helped develop 30 years go.

Are You Looking To Design Your Machine With SEMI S2/S8 Standards In Mind Before Production?

Lewis Bass International Engineering Services offers SEMI S2/S8 design consultation services as part of our greater service offering. Our professional engineering team will meet with you personally to go over your draft designs and suggest improvements, new approaches, and give your team new insight into developing your machine with future compliance to SEMI standards as an actionable goal post in your development.

As part of this service we also offer full cycle consultation to eventual testing and certification of your proposed machine in a timeline that works for all parties involved. Do you happen to have an upcoming project that needs consultation to accommodate a successful SEMI S2/S8 evaluation in the future? Please reach out to us as and describe your project to our sales team.

Common Requests We Will Make In The Process Of Preparing Your Machine For An S2 Inspection

Once our sales team receives a purchase order for SEMI S2/S8 services we provide a pre-inspection checklist that will help you prepare for the evaluation and testing.

As a general guideline, our engineer will perform the following tasks in coordination with your engineering team below:

1) Review the machine’s manuals, BOM, and schematics.

2) Come to your facility and do a multi-day inspection.

3) Provide your team with a punch list of items that failed.

4) Communicate back and forth with you to resolve all identified issues.

5) Start writing the report and putting together the Technical File.

6) Produce a draft report for your to review and make requests.

7) Provide the final report and technical file.

8) Provide a SEMI S2 certificate.

SEMI S2/S8 Evaluations Act As Insurance to Buyers of Semiconductor Equipment

In the semiconductor industry, the SEMI S2 and S8 directives are relied upon as the gold standard for machine evaluation. Many buyers have even begun including them in their terms of contract.

Additionally, SEMI S2/S8 certification proves that your product fulfills the international standards for safety and ergonomics, making international sales of semiconductor equipment an overall smoother process between buyers and sellers.

What Are The Most Common S2/S8 Guidelines?

A typical SEMI S2/S8 service that we get requests for is usually comprised of the S2-0818, S8-218, and S10 sections, with some clients opting for additional sections due to insurance or facility requirements. Another common add-on bundle is Sections 21, 22, 23, for machines that deal with chemical and gas components.

The list below encompasses the most common client requests LBIES receives for SEMI S2/S8 services.

| SEMI® S2-0818E | Environmental, Health, and Safety Guideline for Semiconductor Manufacturing Equipment | |

| SEMI® S8-0218 | Safety Guideline for Ergonomics Engineering of Semiconductor Manufacturing Equipment | |

| Sections Of SEMI® S2 | ||

| SEMI® S2 Evaluation Section 9 Documents Provided to User | ||

| SEMI® S2 Evaluation Section 10 Hazard Alert Labels | ||

| SEMI® S2 Evaluation Section 11 Safety Interlock Systems | ||

| SEMI® S2 Evaluation Section 12 Emergency Shutdown | ||

| SEMI® S2 Evaluation Section 13 Electrical Design | ||

| SEMI® S2 Evaluation Section 14 Fire Protection | ||

| SEMI® S2 Evaluation Section 15 Process Liquid Heating Systems (SEMI® S3) | ||

| SEMI® S2 Evaluation Section 16 Ergonomics and Human Factors | ||

| SEMI® S2 Evaluation Section 17 Hazardous Energy Isolation | ||

| SEMI® S2 Evaluation Section 18 Mechanical Design | ||

| SEMI® S2 Evaluation Section 19 Seismic Protection | ||

| SEMI® S2 Evaluation Section 20 Automated Material Handlers | ||

| SEMI® S2 Evaluation Section 21 Environmental Considerations | ||

| SEMI® S2 Evaluation Section 22 Exhaust Ventilation | ||

| SEMI® S2 Evaluation Section 23 Chemicals | ||

| SEMI® S2 Evaluation Section 24 Ionizing Radiation | ||

| SEMI® S2 Evaluation Section 25Non-Ionizing Radiation and Fields | ||

| SEMI® S2 Evaluation Section 26 Lasers | ||

| SEMI® S2 Evaluation Section 27 Sound Pressure Level | ||

Does Your Facility Sell or Manufacture Semiconductor Equipment?

Please reach out to LBIES today for a free quote on SEMI S2/S8 services for your equipment. We can accommodate rush jobs and lengthier design consultation projects requiring iterative feedback toward eventual testing and certification to SEMI standards as well.