When to consider implementing an annual thermographic inspection for your business

Thermographic inspections sound more complex than they really are.

A Thermographic inspection makes use of specially designed infrared cameras to generate images that show surface heat variations.

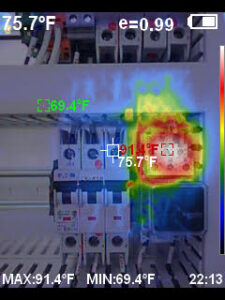

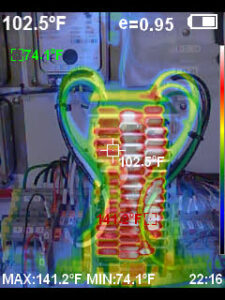

The images captured from inspecting tools, or electrical components are called thermograms. Thermograms visually show abnormally hot electrical panels, electrical components, and the heat signatures caused by excessive friction in mechanical systems.

Themograms can show premature wear and/or potential faults occurring in machinery if the heat signatures are determined by LBIES engineers to be above manufacturer’s specifications for long period of time.

Thermographic inspections are a cost-effective route for analyzing when and where your company’s assets may need to be serviced or replaced down the road. Having a thermographic inspection done as part of a combined plant maintenance program is a recommended course of action for any company seeking to have continual uptime in their industry.

LBIES’s true value in delivering our thermographic inspection service is created when our engineering team takes into account the measured heat signatures and operating temperature ranges of your equipment to provide you dialed in recommendations to mitigate any potential issues in your machinery that may otherwise have created unexpected downtime and/or lost productivity for your company in the future.

What types of equipment does a thermographic inspection cover?

A thermographic inspection performed by Lewis Bass evaluates the following line items:

- Electrical Panels

- Circuit breakers

- Switch-Gears

- Bearings

- Motor-control Centers

- Motor and generator connections, windings, feeders and exciters

Trouble areas show up in the thermograms as hotter spots of infrared energy that a member of the LBIES team can interpret, evaluate, and provide actionable recommendations for improvement and eventual mitigation.

The cost savings of implementing an annual thermographic inspection for your business:

The Federal Energy Management Program (FEMP), performed a study to estimate the cost-benefits of adding an annual thermographic inspection to planned maintenance programs. FEMP determined that implementing an annual thermographic inspection program as part of a generalized predictive maintenance plan can yield a savings of 30-40% over reactive maintenance.

Other independent surveys indicate that, on average, starting an industrial predictive maintenance program results in the following savings:

- Return on investment: 10 times

- Reduction in maintenance costs: 25 to 30 percent

- Elimination of breakdowns: 70 to 75 percent

- Reduction in downtime: 35 to 45 percent

- Increase in production: 20 to 25 percent

Calculating the impact of an annual thermographic inspection in your business:

We recommend that you maintain detailed records of your machine/tool asset up-time, production output numbers, and your allotment of maintenance expenses added to your total maintenance costs over time. A year after implementing your annual thermographic inspection, these numbers will show the return on your investment in implementing this predictive thermal imaging maintenance program for your business.

Lewis Bass International Engineering Services has been doing thermographic inspections for our clients since 2009.

If your company is interested in pursuing the creation of a preventative maintenance plan that incorporates thermographic inspection services, please reach out to Lewis Bass International Engineering Services for a free on-site inspection.