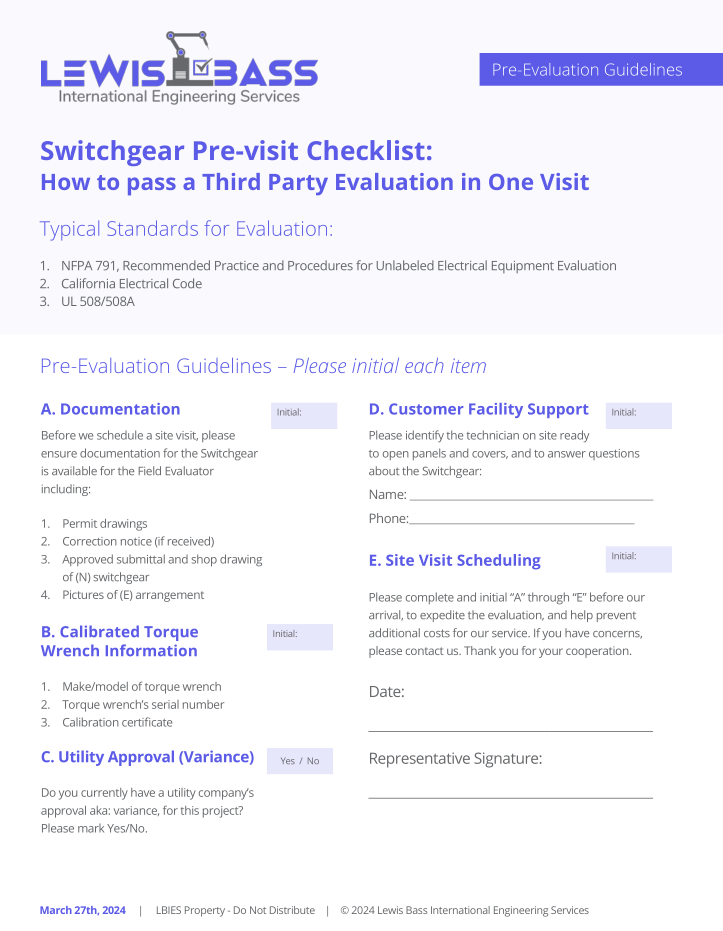

Introducing the Lewis Bass Switchgear Field Label Pre-Visit Checklist

Ensuring the safety and reliability of electrical installations is crucial in any sector, whether it’s solar, residential, or commercial.

As city regulations tighten and the demand for efficient third-party field labeling grows, Lewis Bass International Engineering Services (LBIES) has developed a comprehensive pre-visit checklist designed to make your switchgear evaluations seamless and successful.

What is the Switchgear Field Label Pre-Visit Checklist?

The Switchgear Pre-Visit Checklist by Lewis Bass is a strategic tool aimed at helping clients pass third-party evaluations in just one visit. This checklist is crucial for compliance with national standards, including NFPA 791 and UL 508/508A, as well as specific local codes like the California Electrical Code. It encompasses all necessary preparations across documentation, equipment, and site readiness to ensure a smooth and efficient evaluation process.

Key Components of the Checklist

- Documentation Preparation: Before a site visit, it’s essential to gather all related documentation for the switchgear. This includes permit drawings, any correction notices received, approved submittal and shop drawings of the new switchgear, and photographs of existing arrangements.

- Calibrated Torque Wrench Information: Accurate and calibrated tools are vital for any evaluation. The checklist requires details of the torque wrench including make/model, serial number, and a valid calibration certificate.

- Utility Approval (Variance): It is important to verify whether a utility company’s approval or variance for the project is in place, ensuring that all modifications meet local standards and regulations.

- Customer Facility Support: Identifying an on-site technician who is ready to assist the evaluator by opening panels and answering pertinent questions about the installation enhances the efficiency of the visit.

- Site Visit Scheduling: Completing and initialing the checklist sections before our field evaluator’s arrival can significantly expedite the process, reducing the likelihood of repeat visits and additional costs.

Benefits for Different Industry Use Cases

- Solar Industry: In the burgeoning solar market, ensuring that all electrical components meet safety standards is paramount. This checklist helps in identifying and rectifying potential issues before they can impact system performance or safety.

- Residential: For homeowners, this checklist provides a clear framework for preparing their electrical systems for inspection. This is especially beneficial for ensuring compliance and safety in home renovations or upgrades.

- Commercial: In commercial settings, where switchgear forms a critical part of the electrical infrastructure, the checklist ensures that all systems are up to code and can withstand rigorous usage demands.

Make the Lewis Bass Switchgear Pre-Visit Checklist a Part of Your Company's Workflow

With the Switchgear Pre-Visit Checklist, we are setting a new standard for preparedness in electrical safety evaluations. Whether you’re involved in a small residential project or a large-scale commercial venture, using this checklist can ensure your switchgear installations are compliant, safe, and capable of passing our third-party evaluations efficiently. Remember, being well-prepared can save both time and money while ensuring compliance with the latest safety standards.

You can download our Switchgear Pre-visit Checklist right here.

Do you have a need for our services?

Lewis Bass can help your team identify the most common safety issues in your facility, along with providing immediate referrals to our trusted partners to address them on your behalf.

Not sure what service you need from us?

Take our service identifier quiz here.

Are you uncertain if your equipment is unlisted or not at your facility?

Lewis Bass has you covered here as well: download our unlisted equipment self-identification flyer here.

Do you have a need for an urgent machinery evaluation?

Please reach out to us using our contact form here or call/text us directly on our office line 408-942-8000. We are always available to help with rush jobs and permit-blocking safety situations at your facility.