SEMI S2 report compliance: explaining system conformances and non-conformances

There are not many example SEMI S2 reports (if at all) on the internet.

Due to the confidential nature of both the client’s system’s proprietary functioning and the very nature of the SEMI S2’s licensing requirements.

This blog post will serve as a light introduction to the secret and often hidden world of SEMI S2 reports and the method(s) of categorizing conformity and non-conformity in a SEMI S2 report.

In the following three sections, there will be actual examples of certain SEMI S2 report testing that was performed on actual client systems (with all identifying and proprietary information redacted) that make up the overall percentage score (passing or non-passing) of a system that has been evaluated to SEMI standards.

These three sections will go over CSC (conforms to the stated criteria), CPG (conforms to the performance goal), and DNC (does not conform to the stated criteria) as evaluated per each unique SEMI S2 section and sub-section or SEMI S2 standard and sub-standard.

What does CSC, CPG, and DNC mean in a SEMI S2 report?

The sections of a SEMI S2 evaluation report document the results of the hazard analysis and safety evaluation of the system that is evaluated.

The SEMI S2 safety assessment also documents the conformance or non-conformances of the system designs and documentation to SEMI® S2-0821 and other applicable SEMI guidelines.

The results of the analysis are incorporated into a line-by-line breakdown of the conformance of the system to the SEMI guidelines.

Each paragraph is noted with:

1) CSC – The system conforms to the stated criteria. This means that certain equipment aspects (to which the paragraph pertains) match (conforms to) the criteria stated in the text of the paragraph.

2) CPG – conforms to the performance goal. This is a light non-conformance. It means that the equipment aspects (to which the paragraph pertains) do not match the stated criteria, but they do match the performance goal of the paragraph and they present a LOW or VERY LOW risk according to the risk assessment method of SEMI S10.

3) DNC – The system does not conform to the stated criteria. This means that certain equipment aspects (to which the paragraph pertains) do not match (do not conform to) the stated criteria and do not conform to the performance goal, OR for which there is insufficient information available to reach another conclusion.

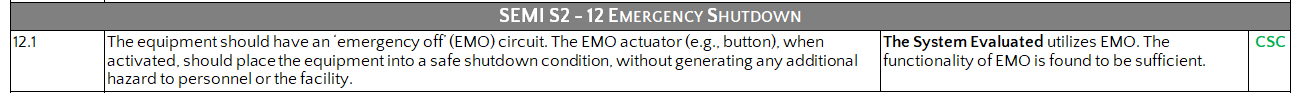

What is an example of a CSC?

This below example is from a real Lewis Bass SEMI S2 report for the SEMI® S2 Evaluation Section 12 Emergency Shutdown which shows a CSC (Conforms to Stated Criteria) rating.

This section features specific assessments regarding the functionality and usage of the EMO (Emergency Off Button or “kill switch”) for the system.

In this case, for the first test in section 12, 12.1, the system is marked as CSC because the EMO button has been verified in the field to successfully turn off the system when pressed.

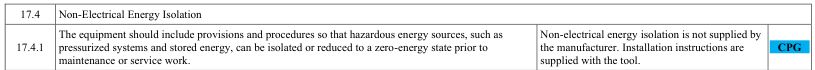

What is an example of a CPG?

This below example is from a real Lewis Bass SEMI S2 report for the SEMI® S2 Section 17 Evaluation Hazardous Energy Isolation which shows a CPG (Conforms to the Performance Goal) rating.

This section features specific assessments regarding the practices for safely isolating hazardous energy sources in the system.

In this case, for this test in section 17, 17.4.1, the system is marked as CPG because a specific Lock-out Tag-out (LOTO) program has not been supplied by the manufacturer, but the system is designed in such a way to be compliant to one.

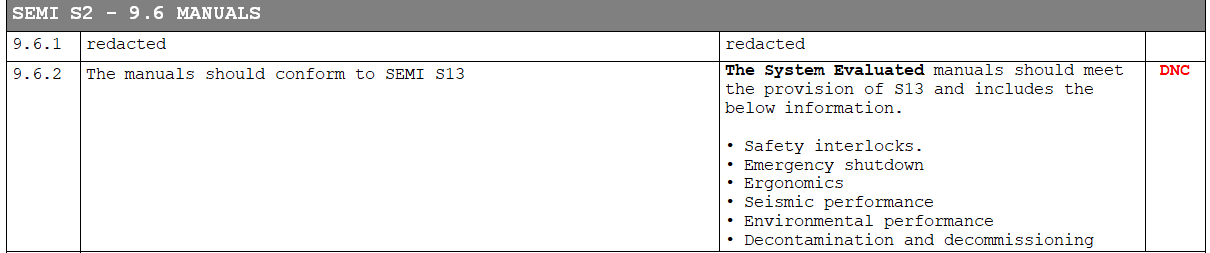

What is an example of a DNC?

This below example is from a real Lewis Bass SEMI S2 report for the SEMI® S2 Section 9 Documents Provided to User (Manuals) which shows a DNC (Does not Conform) rating.

This section features specific assessments regarding the practices for providing accurate documentation and operating manuals to end users of the system.

In this case, for this test in section 9, 9.6.2, the system is marked as DNC because the client-provided operating and maintenance manuals have failed to meet SEMI® S2 Section 13 Electrical Design guidelines by not providing the end user with information on operating the system’s safety interlocks, EMO button, ergonomic usage methods, seismic performance, environmental performance, and decontamination and decommissioning procedures.

How can you make sure that your system receives all CSC ratings?

Building a system that conforms to 100% of the applicable SEMI S2 safety guideline criteria starts with building the machine for compliance.

Since the operating manual, LOTO procedures, and other safety documentation for a system play such a key role in compliance, it behooves you to start with drafting the system’s documentation in parallel with system design when scoping out a new system for development.

Additionally, plan to provide an additional 3-6 months of extra development time to allow for any potential blockers toward compliance to be resolved prior to building the system. You’d be surprised that being an inch to high or an inch to low for the placement of an EMO button is a DNC according to SEMI S8 ergonomic guidelines.

Need help with SEMI S2 system design?

Lewis Bass now offers a service for SEMI S2 design compliance. Request a quote by clicking the link right here.

Test your knowledge: take this blog’s quiz!

Results

Congratulations!

Your knowledge of this week’s blog post was amazing.

Oh no!

You didn’t get them all right this time, but there will be future quizzes in our upcoming blog posts this year for you to try again in the future.

HD Quiz powered by harmonic design

#1. CPG means the system is in compliance with that semi section or standard.

Ooops! That is a wrong answer.

#2. The sections of a SEMI S2 evaluation report document the results of what below?

Select all that apply:

Ooops! That is a wrong answer.

#3. The SEMI S8 standard is the guideline for which safety topic?

Ooops! That is a wrong answer.

#4. Which SEMI S2 section is resposible for the review of Documents Provided to User?

Do you have a need for any of our other services?

Lewis Bass can help your team identify the most common safety issues in your facility, along with providing immediate referrals to our trusted partners to address them on your behalf.

Not sure what service you need from us?

Take our service identifier quiz here.

Are you uncertain if your equipment is unlisted or not at your facility?

Lewis Bass has you covered here as well: download our unlisted equipment self-identification flyer here.

Do you have a need for an urgent machinery evaluation?

Please reach out to us using our contact form here or call/text us directly on our office line 408-942-8000. We are always available to help with rush jobs and permit-blocking safety situations at your facility.

Comments are closed.

One Reply to “SEMI S2 report compliance: explaining system conformances and non-conformances”

[…] in the semiconductor sector. This is why a framework that ensures conformance is crucial. A SEMI S2 safety assessment documents conformance or non-conformance. The assessment is based on the SEMI S2 standard, which stipulates safety […]