Three machine safety situations facility managers need to be aware of

Machine safety is nothing to be taken lightly: here are three safety situations you should be aware of.

Here at Lewis Bass, we have encountered just about every possible scenario involving machine safety and compliance-blockers in the course of providing our third party electrical evaluations to our clients.

In this week’s blog post we are going to cover three safety and compliance topics that we haven’t seen addressed online and offer you routes toward addressing them if you ever spot them at your facility.

In this series of blog posts we will cover the situation where these safety issues are found, the solution to how to address these found issues, and the cost of doing nothing in both regulatory fines and insurance costs when worker or facility safety is at stake.

The three safety situations we will be covering are:

- The NRTL CE marking and the risks of non-compliance with your local city/AHJ.

- Power button requirements for machines with moving parts and pinch points.

- Lack of proper protective barriers on dangerous equipment.

NRTL CE Markings

The Situation:

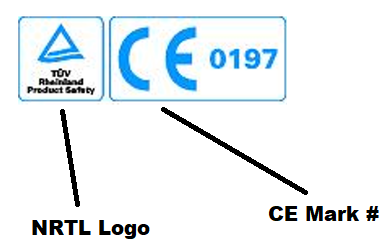

Your machine has an NRTL mark on it and also a CE marking in close proximity. You could have one machine or a dozen machines with this type of marking in your facility and the local AHJ may have even signed off on these tool(s) without digging much further. So, what exactly is the safety situation in this example?

When a reportable incident occurs at your facility involving a fire that points to being started by any of of these machines, you’ll soon find out that the documentation behind the NRTL CE marking* is for an NRTL giving a CE mark, and is not actually a field evaluation label for suitable compliance reasons in your jurisdiction and according to NFPA code.

*Note: CE compliance, however, is not all bad: it shows that the machine was built to certain applicable directives which allowed for full CE certification in the EU, which also means the machine won’t be too costly to bring up the US NFPA design standards.

The Solution:

Have an FEB like Lewis Bass or others in your jurisdiction perform a 3rd party field label evaluation for these tool(s).

Lewis Bass has also created a handy safety flyer for you to self-identify your unlisted or CE-marked equipment, too.

Not only will you have the piece of mind knowing that the research has been done on the equipment and that your insurance will cover your losses in the event of a reportable incident, but you will also be ensuring value remains in the equipment for other users down the line if you happen to sell it second hand, due to the issue of compliance in North America already having been addressed.

The Cost of Doing Nothing:

In the event that a tool or tools bearing the NRTL CE mark in North America leads to a reportable incident in your facility, the insurance company you have for your facility is within its right to waive payment for losses if it is proved that this machine was never field labeled for North American use. Additionally, fines can be levied by OSHA against your company in the event that these non-compliances are reported to them and can be as high as $13,653.00/day for your facility if left unaddressed.

The Need For Two Power Buttons

The Situation:

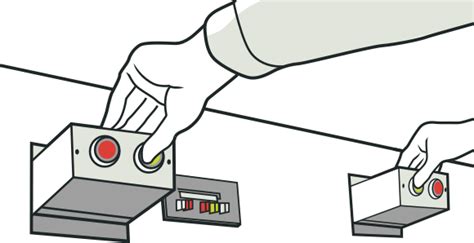

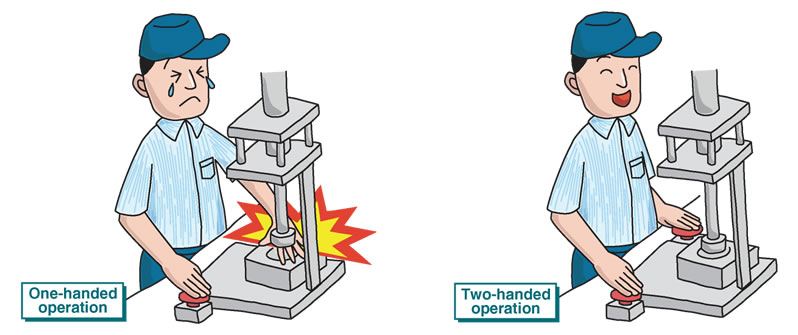

A machine in your facility has multiple warning signs on it showing areas of potential injury due the functionality of the machinery and its intended use case. This could be a hydraulic press, a crimping machine, or any other type of desktop or standalone machine engaged in the production of items using directed force or other methods of forming.

The machine in question has only one power button and allows for the potential of harm to occur if a worker were to both reach into or make contact with a part of the machine identified as hazardous while also reaching for the power button to turn on the machine.

The Solution:

Install two power buttons on each side of the front of the machine that require a worker to engage both buttons at once to turn on the machine.

Adding this second power button will make sure that both of your worker’s hands are accounted for and will fully mitigate any potential injuries that could have resulted from accidental contact with the machine.

The Cost of Doing Nothing:

While installing two power buttons is not necessarily required and certainly won’t get you flagged by OSHA or during an electrical evaluation for a field label, your facility may be subject to a steep payout of workers compensation to any affected worker that is injured by this machine in the course of their work.

A typical worker’s compensation claim can be as much as $40,000.00 with the average employee getting around $20,000 for their payout.*

*Source: https://www.augustaworkerscomp.com/average-workers-comp-settlement-amount-can-expect/

A Machine With No Protective Barriers

The Situation:

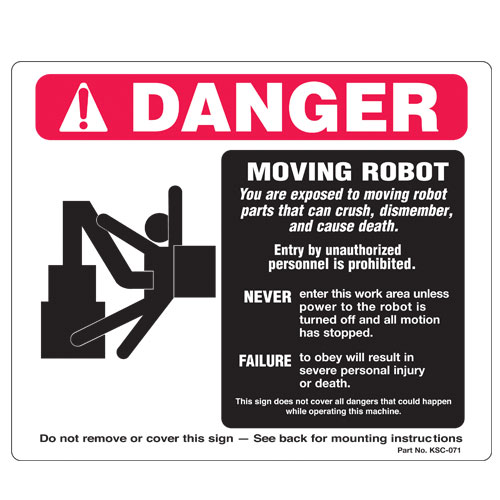

A machine at your facility involved in production has no plastic or metal shielding around pinch-points, crush-zones, and other harmful or dangerous areas.

The Solution:

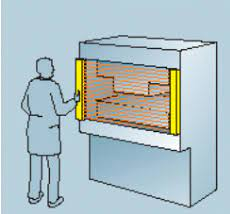

Install protective barriers to cover these areas of potential injury and/or setup a light-curtain to automatically detect movement going into a dangerous area of the machine as demonstrated in the picture below.

The red horizontal lines between the yellow areas are the depictions of the opto-electronic sensor overlap that detects and then shuts down a machine prior to injury occurring

The Cost of Doing Nothing:

Under OSHA Standard number 1910.212 , “General Requirements for All Machines”, 1910.212(a)(1) , “Types of Guarding” machine safety guarding is a clear requirement for OSHA compliance:

One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, in-going nip points, rotating parts, flying chips and sparks. Examples of guarding methods are-barrier guards, two-hand tripping devices, electronic safety devices, etc.

If a recordable incident occurs at your facility involving worker injury that can be traced back to machines lacking the required safety guarding to be in operation, the penalties can be per machine and per day and start at a minimum of $13,653.00 for each violation and $13,653.00 per day after that the issue is not addressed in the facility. This is in addition to workers compensation claims that your worker may file against you as well.

For more guidance on protective barrier requirements per OSHA click here.

Do you have a need for our services?

Lewis Bass can help your team identify the most common safety issues in your facility, along with providing immediate referrals to our trusted partners to address them on your behalf.

Not sure what service you need from us?

Take our service identifier quiz here.

Are you uncertain if your equipment is unlisted or not at your facility?

Lewis Bass has you covered here as well: download our unlisted equipment self-identification flyer here.

Do you have a need for an urgent machinery evaluation?

Please reach out to us using our contact form here or call us directly at our office line 408-942-8000. We are always available to help with rush jobs and permit-blocking safety situations at your facility.